Lone Star Drone

Apr 14, 2025

Saving Cold, Saving Costs

When it comes to refrigerated storage facilities, keeping the cold in and the heat out isn't just about performance—it's about profitability. From energy efficiency to inventory protection, the margins in cold storage facilities are tightly bound to one factor: insulation integrity.

Over the past six months, Lone Star Drone has worked closely with a major cold storage facility in Hutchins, Texas, using advanced aerial thermal imaging to detect temperature variances and energy inefficiencies. The results were more than impressive—they were game-changing.

The Mission: Reduce Wasted Input Costs in Cold Storage

Our client, a leading food distribution chain, was experiencing unexplained increases in internal temperature and energy usage across their Chick-fil-A cold storage warehouse in Hutchins, Texas. Despite their cooling systems working overtime, key storage zones were registering several degrees above optimal levels. This led to growing concerns about inventory quality, higher electric bills, and the long-term stress being placed on their refrigeration systems.

Traditional inspections hadn’t revealed any clear cause—no obvious equipment failures or visible insulation issues. That’s when they turned to Lone Star Drone for a more advanced, data-driven solution: aerial thermal inspections.

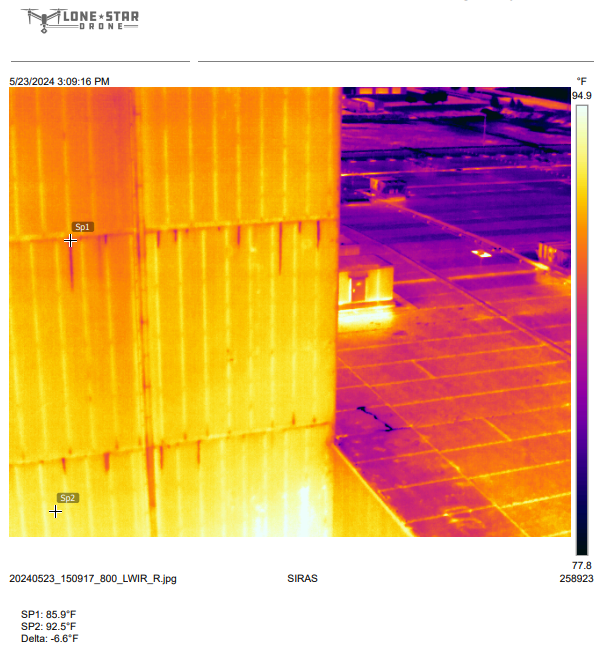

Using high-resolution infrared thermal cameras mounted on aerial drones, we scanned every square foot of the building’s roof and walls, identifying heat signatures invisible to the naked eye. Over the course of six months, we conducted multiple flights and compiled a detailed thermal map of the facility, tracking where—and why—temperature gains were happening.

The Power of Perspective: Why Drones Make the Difference

Unlike handheld thermal devices or static rooftop sensors, drones provide a full 360° aerial view of a building’s exterior envelope—allowing us to analyze the roof, walls, vents, and door seals in a single flight. This broader perspective allowed us to identify:

Thermal leaks in roof seams and wall panels

Moisture collection zones causing temperature deltas

Insulation gaps that traditional inspections missed

Patchwork repairs that affected heat absorption differently

Before vs. After: The Impact of Actionable Data

In our first report, we flagged several problem areas. The most notable thermal deltas were found along the north-eastern edge of the roof and in the southwest corner, where temperature differences were consistent with either water accumulation or inadequate insulation.

These findings enabled the facility's management to take focused action—patching, sealing, and upgrading insulation where it was needed most. When we returned for the final inspection on January 16, 2025, the difference was clear. Our thermal scans found no significant thermal leaks, and the previous hotspots showed normal thermal behavior.

From the report:

“On January 16th, 2025, we performed a thermal inspection that resulted in no faults found. The areas that have been a concern previously have been repaired and showed no abnormal thermal signatures. It is our belief that no significant thermal leaks exist now.”

This is the kind of efficiency cold storage operators dream of—no guesswork, no wasted time or money. Just data-driven results.

Real ROI: The Financial Case for Thermal Inspections

In cold storage, energy costs can consume up to 60% of a facility's operational expenses. Even a minor breach in insulation can translate into thousands of dollars in lost cooling each month. By using thermal inspections to locate and address these weak spots, Lone Star Drone helps cold storage clients:

Reduce energy costs

Prevent spoilage and product loss

Extend the life of refrigeration systems

Improve sustainability benchmarks

Stay compliant with temperature regulation standards

And the best part? A single thermal inspection can often pay for itself by identifying inefficiencies before they spiral into costly problems.

Our Approach: Excellence is Our Mission

At Lone Star Drone, we're more than just drone pilots—we’re mission partners. Founded by a U.S. Army veteran, we bring military-grade precision and reliability to every flight, every inspection, and every report. We prioritize safety, accuracy, and delivering solutions that drive real business impact.

Whether you're managing a single facility or an entire portfolio of cold storage centers, we can customize a thermal inspection plan that fits your needs, schedule, and budget.

Ready to Get Started?

If you're operating a cold storage facility in Texas—or anywhere in the U.S.—it's time to upgrade your maintenance strategy with aerial thermal inspections.

Stop guessing. Start seeing.

Let Lone Star Drone help you keep your cool—literally. Reach out today to schedule a demo or request a quote. Because when it comes to cold storage, every degree—and every dollar—matters.